Written for Airwaysmag.com/Airchive.com

Regular Airways readers have seen our stories about the Bombardier CSeries first flight, and our tour of the Flight Test Vehicle Final Assembly Facility. But fear not, we’re not done yet. The day after the events at Mirabel Airport, Bombardier invited us to their facility in St. Laurent, Quebec, not far from Montreal’s Pierre Elliot Trudeau Airport. We were being treated to a visit at the CSeries Customer Experience Centre. Our hosts were Sam Cherry, Director, Product Strategy; Martin Gignac, Product Manager & Strategy; and Marc Duchesne, Director of Public Affairs and Communications.

Mr. Gignac suggested we act as if we were potential customers for the CSeries. He started off showing us a presentation outlining the features of the plane. It was only the morning after the first flight, but the Powerpoint had already been updated with shots of FTV1 in the air; nice touch! We then moved to a large, touch-screen computer display. Mr. Gignac walked us though the CSeries website, and then selected a page which was designed for use only with airline customers. You won’t find it on the web.

On this special page, customers can input the specific requirements of their flights and compare the economics of their existing or proposed fleet to the CSeries. We tried it out with a few obvious competitive aircraft, both currently flying and in development. As we expected, the CSeries came out ahead. It’s a neat piece of software, but we’re pretty sure that potential airline customers will do their own extremely in-depth analysis before placing any orders.

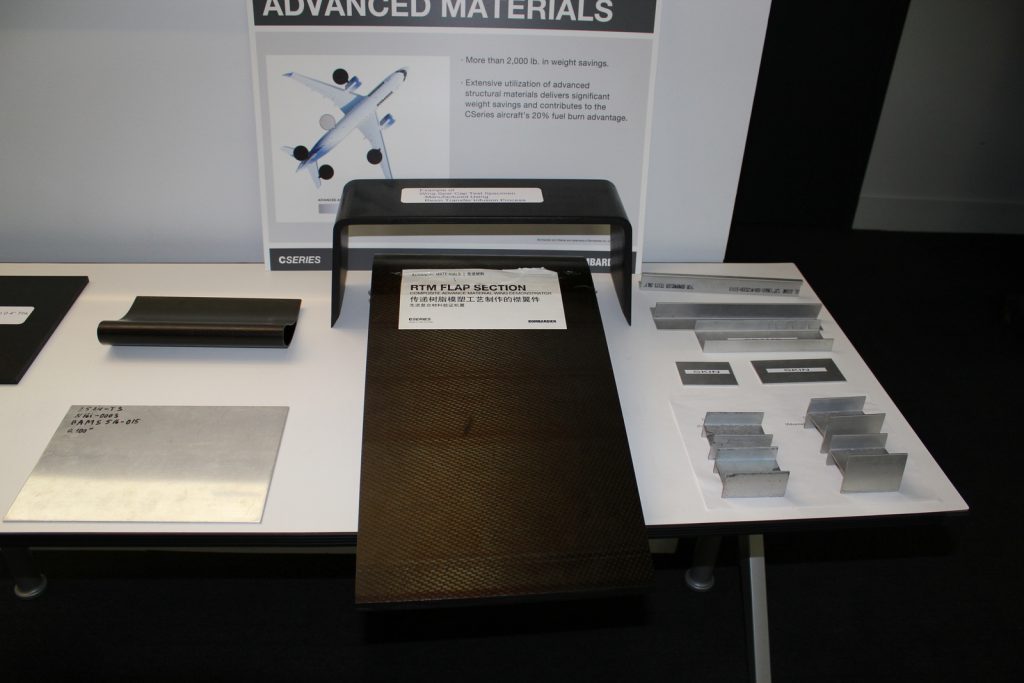

Assortment of materials used in the construction of the CSeries. An aluminum-lithium panel is lower left.

Mr. Green took a bit of time to show us a display of some of the materials that are being used in the construction of the CSeries. He’s proudly from Bombardier’s Belfast, Ireland facility. We had a great discussion about the plane’s carbon-fibre wing that’s built in Belfast and then shipped via sea to Mirabel. Mr. Green also showed us samples of the aluminum-lithium material that’s being used to build the fuselage. The new material is both lighter and stronger than the standard aluminum that it replaces. All of these advanced materials contribute to a 2,000 lb weight savings for the CSeries, which directly relates to a 20% reduced fuel burn advantage over current single-aisle jets.

We then moved to the flight deck configuration display. This is a very basic mock-up, showing the avionics displays and a side-stick controller. We did notice, according to the instruments, that the room was climbing – a bit of fun programmed by the engineers. Rockwell-Collins will be supplying the advanced avionics and flight control suite for the CSeries.

Bombardier designed the CSeries as a fully “Fly-By-Wire” (FBW) aircraft, which means that all flight control surfaces and on-board systems are controlled electronically, rather than with direct, physical and mechanical connections. The first FBW passenger aircraft was Concorde. More recently, all Airbus planes since the A320 are digital FBW, as are the Boeing 777 and 787. For the CSeries, Bombardier opted to use side-stick controllers on the flight deck. This is similar to Airbus’ controls, and differs from the traditional control column and yoke in Boeing’s planes.

The flight control system is, without any doubt, state-of-the-art. When you look at the photo of the flight deck, you’ll see that it’s dominated by large, flat-panel displays. And like so many computer-based systems, it isn’t just the hardware that makes the system functional; it’s the software. The team that developed the code for the CSeries flight control system had to integrate all of the sensors, control surfaces, hydraulic and electrical systems, communications, navigation and auto-flight systems.

The system is “smart”, so that the flight crew is presented with information when they need it, and in a level of detail that’s required for the current phase of the flight. The displays can be tailored to fit the pilots’ and the airline’s processes and procedures. A “heads-up” display is an option on the CSeries, which allows pilots to keep their eyes looking “outside” when they’re flying an instrument approach. They can see key aircraft performance information on a see-through display that folds down in front of the window, instead of having to monitor the instruments on the panel, and then transitioning to look for the runway during the final few seconds of a low approach. It’s a great safety feature. We’re hoping that on our next visit to Bombardier, we’ll have a chance to “fly” the CSeries simulator.

Stepping through the forward cabin door, the “lobby” was open and airy. Straight across the aisle was the galley, serviced by a door on the starboard side. To the left, a lavatory. The design of the lavatory was influenced by Rob Dewar, Vice President & General Manager of the CSeries program. You see, Mr. Dewar is a tall man at 6’ 3”, and he challenged the CSeries cabin designers to create a lavatory in which he could comfortably stand. The team did it.

Turning to the seating area, the mock-up has two rows of first/business class seats, and five rows of economy seating. Our first impressions? There is nothing about the CSeries that remotely suggests “regional jet”. Passengers are going to love it. The windows are really large, as big as those on a Boeing 777. They’re close together, high on the sidewall, and passengers can look outside from any seat. Bombardier is offering airlines an optional “electro-chromatic” shade, similar to the technology used by Mercedes-Benz in their high-end cars. The system can go from clear to full-shade in only 7 seconds, much faster than the electronics shades on the Boeing 787.

In real life the CSeries jets will seat between 110 and 160 passengers. targeting the “sweet spot” between the smaller RJs and the larger single-aisle planes from Airbus and Boeing. The CSeries design team determined that five-seats across was the optimum economy cabin configuration in a three and two, single-aisle layout. With that in mind, the fuselage has enough room for comfortable 18 ½” wide seats. The middle passenger on the three-seat side gets a bonus extra half-inch, with a 19” wide seat. And after doing a bit of quick math, it doesn’t seem that there’s any way that seat width can be reduced to squeeze in a sixth seat across. So it’ll be five comfortable seats in a CSeries.

Sitting in a window seat, we noticed that the sidewall is barely curved, from the overhead bins right to the floor. Given the “clean-sheet” design of the CSeries, Bombardier wasn’t constrained by a legacy fuselage size. Think about it – the Boeing 737’s design goes all the way back to the mid-1950’s 707. The Airbus A320 series has passed its 25th birthday. As much as both of those manufacturers do to re-design the interiors of their planes, they can’t change the fuselage shape. That’s why, as a window-seat passenger, your legroom might be restricted on a 737 or A320. Not so in a CSeries plane.

These days, passengers seem to be bringing half of their house onto a flight as carry-on baggage. The CSeries team designed overhead bins that should be able handle the current onslaught of rollaboards. The bins are asymmetrical; above the two-seat side, they can handle 22” bags, and the bins on the three-seat side are 24” deep. The bins are easy to open, and swing down so that they don’t intrude on the aisle.

The mockup’s rear galley was set up with food carts, and Mr. Duschene rolled one out into the 20” aisle to show off another CSeries feature. As you can see in the photo Mr. Duschene is able to get past the cart. Flight Attendants who have visited the mockup were most impressed. Passengers will be, too.

Finally, Bombardier is providing a “Persons with Reduced Mobility” (PRM) lavatory in the CSeries. The lav has been designed to accommodate physically-challenged passengers who might have in-flight wheelchairs or have difficulty moving in tight spaces. The lavatory’s side wall is hinged. When it’s opened along with the door, it provides a large entryway for easy access to the lav. Nothing else in the cabin needs to be reconfigured to use the PRM lavatory. It’s a smart design.

It’s likely that passengers on a CSeries jet won’t really notice all of the unique features that the design team and human factors specialists came up with to improve the in-flight experience. But if passengers get off a CSeries and say, “That was a nice flight,” that would be the highest praise Bombardier’s team could achieve.

We’re looking forward to our return visit to Mirabel for the CS300 rollout, and a look at FTV5, which will have a full passenger cabin. Many thanks to our friends at Bombardier Aero for arranging our tour.