Boeing’s Dreamliner Gallery is located near the 787 assembly building in Everett, Washington.

Photos: Howard Slutsken

Written for the Airline Passenger Experience Association

APEX Experience Magazine – Issue 5.5 – September/October 2015

At Mock Air, APEX’s unofficial carrier, we’re all about the #PaxEx. At least we would be, if we were an actual airline with real aircraft. But one can never be too prepared, so we recently spent a morning at Boeing’s “Dreamliner Gallery,” to think about fitting out the interiors of our fictional fleet of 787s.

The 54,000 square foot facility has been open for eight years, and was a “paradigm shift in our interaction with our customers,” says Dan Olson, Dreamliner Gallery Manager. “Before this facility existed, Boeing would send documentation to the airline, just a big manual with listings of things. It took a long time, a lot of back and forth, and no real synergistic interaction. The showroom opened to show off [the catalog of] products for the 787, but it’s a lot more than that.”

Located near Boeing’s massive wide-body commercial aircraft plant in Everett, Washington, the Dreamliner Gallery mixes the feeling of a high-end home furnishings store with a private and secure space for airline executives to choose the interior elements of their 787s. In deciding on everything in the cabin from the forward lavatory to the aft galley, airline teams might visit the Gallery numerous times, in a process that can start more than two years before the planned delivery of a new Dreamliner.

“We tried to develop a space for our customers to be quite comfortable, and really focus in on the conversation of configuring their airplanes,” says Kent Craver, Regional Director, Cabin Experience & Revenue Analysis. Airline customers set up in one of two “Home Base” suite of rooms, which include a large lounge area, a fully-connected, high-tech board room, and private office.

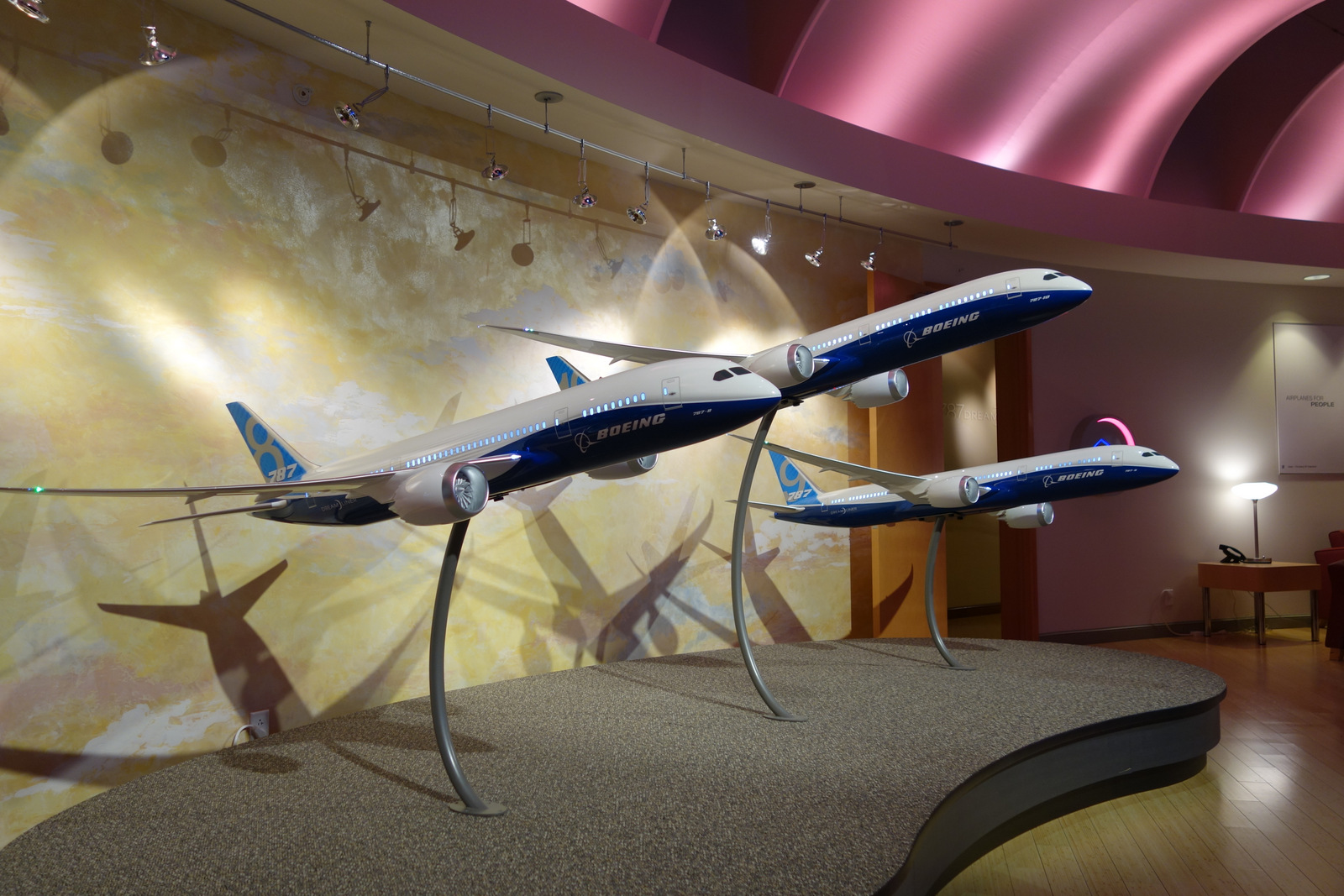

The gallery reflects Boeing’s “Sky Interior Design” philosophy, which began with the 787, and now includes the 747-8 and 737, and upcoming 737MAX and 777X interiors. Visitors enter the gallery through a low-ceiling, jetway-like anteroom, which opens into a dramatic, arched foyer. The foyer mirrors the cathedral entry that passengers may experience when entering a Dreamliner. Other design elements of the 787 program are found throughout the gallery, including the iconic crescent logo. Art-deco-style posters featuring classic Boeing aircraft are strategically placed, along with comfortable seating areas and private rooms, where airline teams can meet with equipment suppliers. And there’s a large display with a Dreamliner model for every airline customer, set up in an undulating wave, led by launch airline ANA’s 787-8.

Our first stop was the Galley & Lavs showroom. It was a bit surreal to see disembodied lavatory modules and galley rack units, all beautifully lit and sitting out in the middle of the showroom. Along one wall is a long, curving display of every galley appliance and cart that’s been “pre-qualified” for the 787. It can take two years for a galley fitting to be certified for an aircraft, with testing required down to the component level, so having a wide selection of items in the 787 catalog makes the process far more efficient.

Off to the side is what Olsen calls the “Iron Chef” kitchen, with multiple power and water hookups, so that all of the fully-functional display appliances can be tested. “We’ve got it all under one roof, and you can try everything out side-by-side. Anything from convection, steam, and microwave ovens; to water boilers and coffee makers,” he says.

The kitchen is also equipped with an audio system that reproduces the sound profile in a flying 787, cycling through the sound in the forward, middle, and aft galleys. So, for example, a trash compactor could be tested out, with the customer better able to understand the perceived noise the appliance would generate during flight.

Next up was the Seats & IFE (In-Flight Entertainment) showroom. Rows of seats are lined up for airlines to test. “We have catalog seats that any airline can come in and select, that are pre-certified. The lead time on a catalog seat is going to be quicker,” says Olson. If an airline decides to go “off catalog” and develop its own passenger seat, it becomes Buyer Furnished Equipment, or “BFE” in Boeing parlance. The development and manufacture of the new seat has to be carefully worked into the aircraft production schedule.

Olson and Craver see a trend in cabin configuration away from 3-class, including first class, to 2- or 2-plus class, with business and economy; augmented with premium economy. The showroom includes economy, premium economy, and business class seats of different configurations. Not surprisingly, there aren’t any first class seats in the showroom, given the bespoke nature of airlines’ first class offerings.

IFE systems from Thales and Panasonic are on display, each with a selection of functional screens. Although wireless IFE is coming, “there’s still a strong desire for long-haul embedded systems, especially in premium cabins, and the screens are still getting larger, even in economy. We’ll continue to see it evolve,” says Craver.

A 787 cabin mock-up is in the next showroom, where airlines and Boeing engineers can test out new seats, configurations, and cabin fittings. Craver explains that an airline might have a new first-class seat, so Boeing’s team would create a foam, dimensionally-accurate copy of the seat, and then check how the seat affects passenger flow in the aisle, for example.

Airlines might spend a lot of time in the “Color & Materials” showroom, put together by Boeing’s decades-long design partner, Teague. Fabrics, yarns and color panels can be tested in the lab’s three-row cabin section, which is equipped with the 787’s LED lighting system. The RGBW system of red, green, blue and white LEDs can be programmed in an almost infinite number of ways, “painting” the neutral white and gray base color palette of the Dreamliner. Airlines have also tested dinnerware, and have even checked the appearance of food, under different lighting profiles.

Furnishings follows next, which includes cabin dividers and other fittings, as well as crew seats and safety equipment. Crew Rest & Flight Deck is the final showroom, with examples of the above-cabin crew bunk rest areas, and a full-sized flight deck representation, with non-functional instruments and controls.

Boeing recognizes that airlines will have varied fleets, perhaps with similar interior designs and seating. Craver explains, “Your brand promise will always be the same, but our goal is that it will always be a better experience when it’s on our airplane.” So, while we want that experience to be perfect, it’s clear that designing the interior of a new 787 takes a lot longer than a morning. But just like at Mock Air, it’s great to know that at Boeing’s Dreamliner Gallery, “it’s all about the #PaxEx.”

Read the original story in APEX Experience Magazine – Issue 5.5