Written for AirlineReporter.com

Today is the 50th birthday of the legendary Pratt & Whitney Canada PT6 turboprop. That first engine was delivered to Beech Aircraft Company for installation onto an aircraft that would become the equally-remarkable Beechcraft King Air.

The PT6 had its genesis at what was then the United Aircraft of Canada Limited (UACL) factory in Longueuil, Quebec. In the mid-1950s, UACL had looked at the market and determined that there was a need for a small, efficient turboprop in the 500-shaft-horsepower (SHP) range. They felt there was technology available to replace then-current radial piston engines that dated back to the 1920s, like the P & W Wasp.

So in 1957, a group of 12 young engineers got together to design a powerplant that was unlike any engine of its time. Turboprops of the day were either massive, such as the 4,000 SHP Allison T56 that powered the Lockheed C-130 Hercules, or they were early-generation and inefficient, like the Rolls-Royce Dart that flew on the Vickers Viscount.

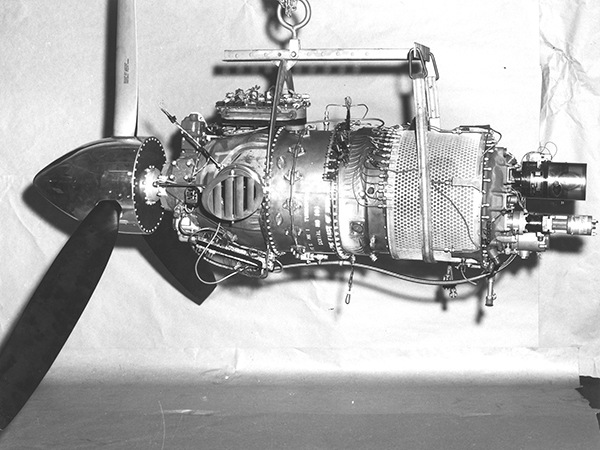

The engineering team made design choices that would stand the test of time. They separated the gas generator and the power sections of the turbine. Think of your car – the gas generator in the PT6 is like your engine, and the power section is the transmission. Other turboprops had the gas generator directly connected to the power section. If that was in your car, it would be like trying to start and drive it with the transmission always engaged. By splitting the engine, starting was much easier and maintenance was hugely simplified. The design is also called a “free turbine”.

The team also decided to make the PT6 a “reverse flow” engine. If you look at a PT6A, say, on a deHavilland Canada DHC-3T Turbine Otter, you’ll see that the engine’s air inlet is under and behind the propeller. The air travels below and to the rear of the engine before it makes a 90-degree upward turn, enters the generator, and changes direction a few times as it gets compressed and ignited. The exhaust is in the forward part of the engine, not in the back. If you look carefully at this video, you’ll see how the air flows through the engine. The two main sections are separate, with the forward (power section) driving the prop, and the rear (gas generator) driving the accessories at the rear of the engine.

Since the first PT6 was delivered 50 years ago, Pratt & Whitney Canada has impressively improved the engine, taking advantage of the many advances in material technologies, manufacturing processes, aerodynamics, and electronics. Today’s PT6 is up to four times more powerful than the first turboprop, with nearly 20%-lower fuel consumption.

The PT6’s statistics are impressive. Over 51,000 engines have been produced, powering more than 130 different applications. There are more than 69 different models, boasting 500 SHP to over 2,000 SHP. You’ll find PT6s in planes and helicopters, and the engines have also powered boats, cars, and trains. In 1967, a PT6-powered racecar even led the Indy 500 until 8 miles from the end, when a $6 transmission bearing failed.

You might have flown on a flight in a plane powered by the PT6, such as a deHavilland Canada DHC-6 Twin Otter or DHC-7 STOLplane, a Beechcraft 1900, Shorts SD360, Embraer Bandeirante, or Pilatus PC-12. And there are a huge number of business aircraft applications, including AirlineReporter.com’s Editor’s favorite, the Beechcraft Starship. PT6s, everywhere!

Over 7,200 operators worldwide are flying aircraft powered by the PT6, and have logged over 385 million flying hours. P&WC says that if you were flying a PT6-powered plane at a speed of 310 mph, that would be like going to the moon and back 250,000 times. If any engine could do that, it would be the PT6.